Unplanned downtime can be catastrophic. eTrack has you covered.

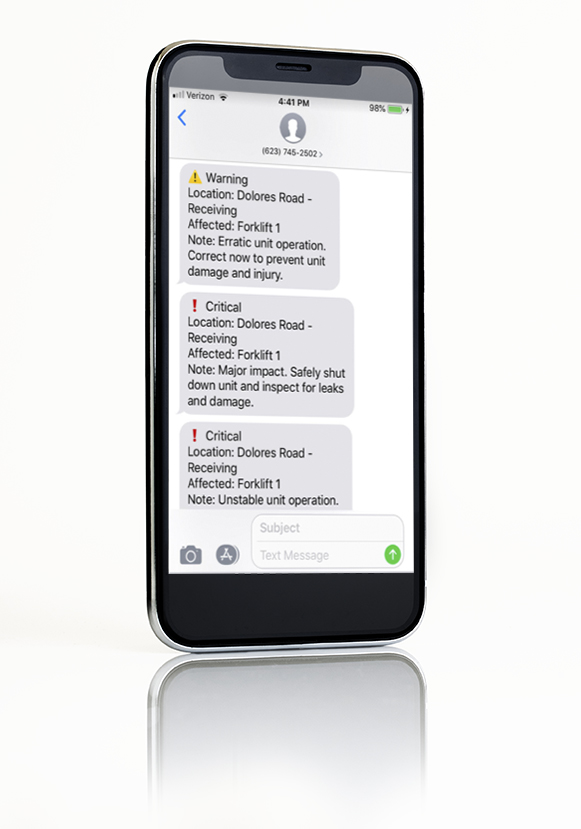

eTrack combines multifunctional sensors, secure communications and our proprietary rules engine to deliver actionable insights via real-time alerts and dashboards through existing channels or APIs to your existing ERP/FM systems

Unplanned downtime

Employee safety

Fleet management complexity

Downtime

Lost productivity from safety incidents costs US businesses over $60B /year.

Forklifts incidents = $1.8 Billion in lost US productivity.

Safety

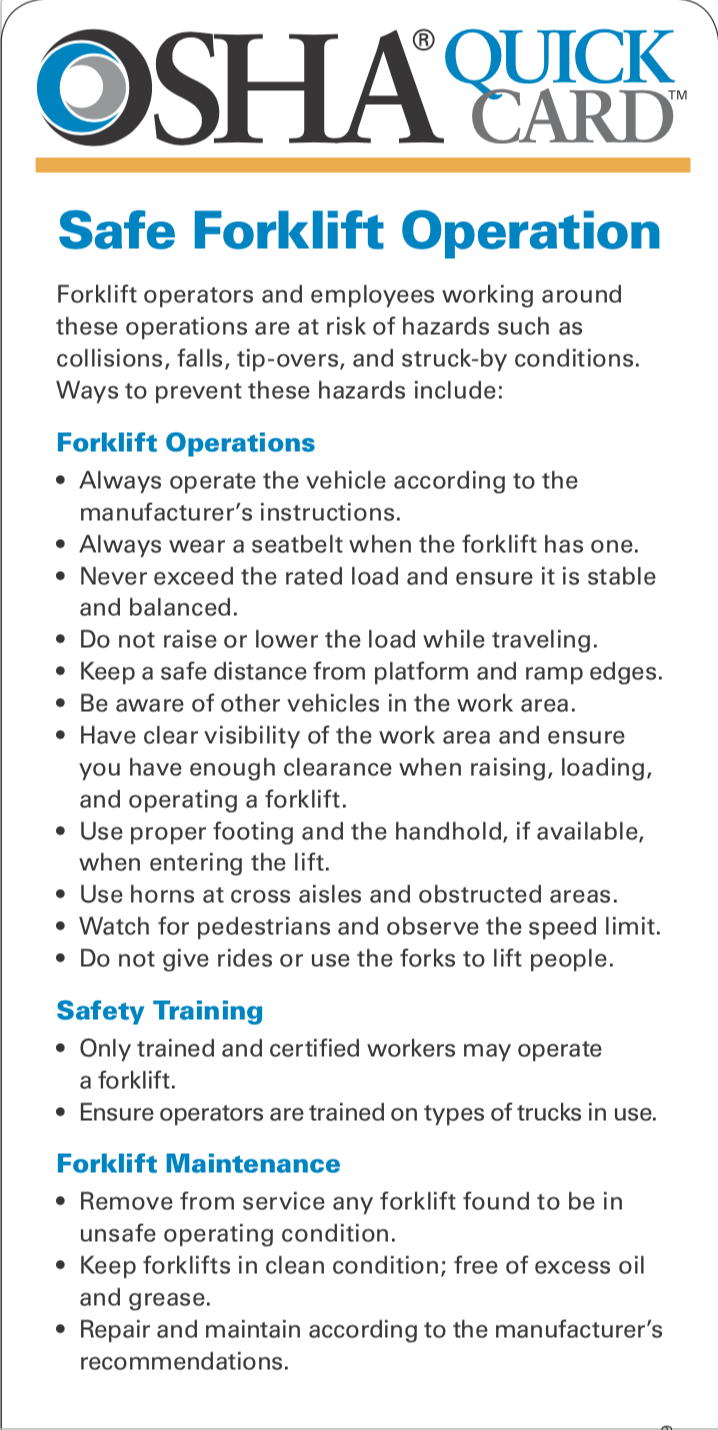

Annually, 1 in 10 forklifts is involved in a safety incident.

Every four days someone dies in a US forklift incident.

Fleet management complexity

Heavy machinery can last for 60 years or more.

Most fleets have multiple brands, ages, types, and levels of technology.

eTrack’s live dashboards enable visibility of all your assets in one view and integrate with your existing ERP system through APIs.

Uptime

Predictive alerts for all your equipment enable proactive repairs, up to 10x cheaper than reactive maintenance.

Anticipate and avoid unplanned downtime and accidents in your operations before they happen.

Employee Welfare

We keep operators ahead of equipment failure and incidents to save money and lives.

Managers gain operational insights for training, safety, and OSHA compliance.

One View of Your Fleet

eTrack provides asset tracking, real-time alerts and actionable insights for your heavy equipment of any brand or age.

Real-time Alerts & Dashboards

eTrack provides visibility across different ages, brands, equipment types, and technology levels.